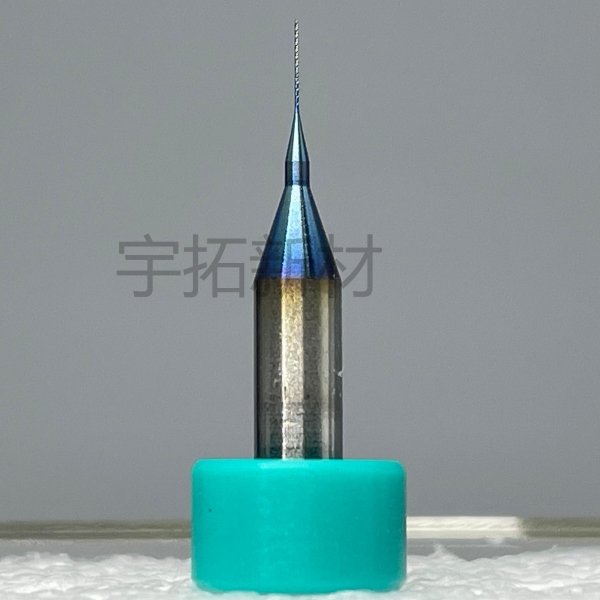

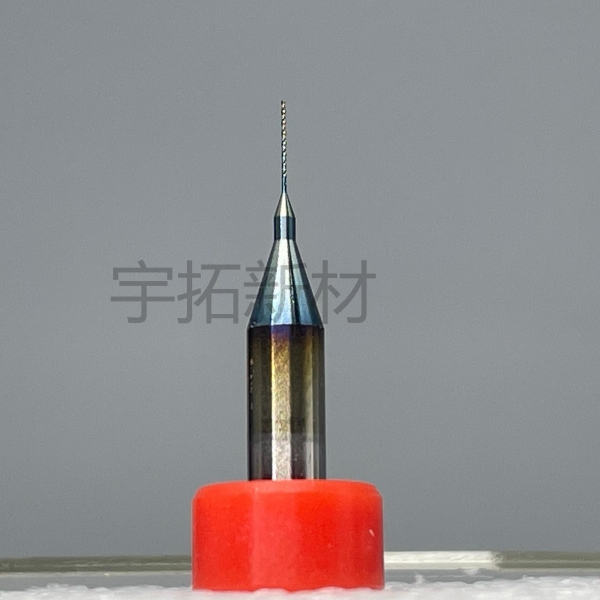

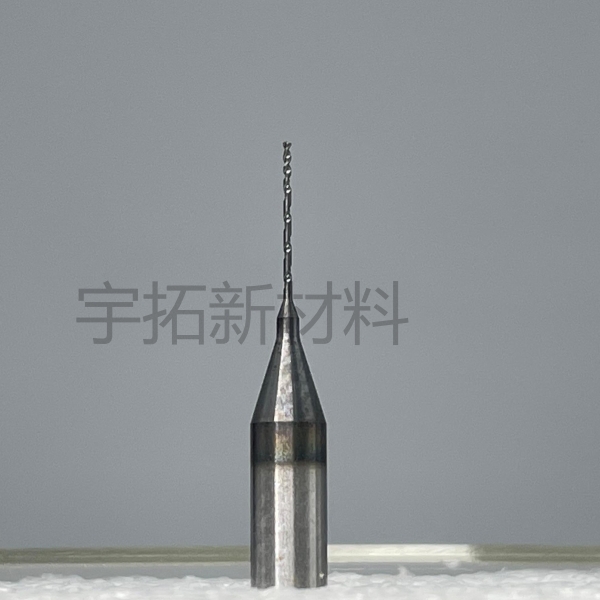

product name | Nano superhard diamond hard plate milling cutter | |||||||||

Product description, cutting characteristics | The blade surface is coated with superhard nano-diamond wear-resistant coating; it is suitable for various medium and high TG, halogen-free plates, especially ceramic plates, high TG plates, metal substrate and other hard plate forming processing. | |||||||||

size of product | Cutting edge diameter mm | 1.00 | 1.10 | 1.20 | 1.30 | 1.50 | 1.60 | 1.80 | 2.00 | 2.40 |

The blade length is mm | 7.50 | 7.50 | 7.50 | 7.50 | 8.50 | 8.50 | 9.50 | 9.50 | 9.50 | |

* If you have special needs, you can communicate customization | ||||||||||

material | Tungsten carbide rod: Tungsten carbide WC content 92%-94%; Cobalt Co content 6%-8% | |||||||||

Component of coating | Diamond: carbon element C content is 100%; conductive diamond: carbon element C content is 99.9%, boron B content is 0.1%, film thickness: 10um±2um; hardness: 9500HV±500HV; friction coefficient: 0.3 | |||||||||

Coating effects | Ultra high hardness, ultra wear resistance, ultra high thermal conductivity, ultra low friction coefficient, micro-cutting effect | |||||||||

Application advantages | Solve the problem of ultra-hard plate processing; greatly improve the life; improve the quality of the edge of the plate; reduce the cost; reduce the change of knife and rework to improve efficiency. | |||||||||